Solder Materials -Products

The die attach process remains a key step in the manufacture of power packages to ensure product reliability. Heraeus solder wires ensure excellent thermal performance of the solder connection and improve customer’s yield and product reliability.

The demands on the reliability of electronic components are rising: High power applications and rising customer expectations put pressure on the thermal performance of solder pitch. Thermal and mechanical fatigue defects in electronic components are caused primarily from successive on/off cycling. To maximize reliability, engineers must identify the optimal combination of material performance and properties.

A perfect solder connection is crucial for the thermal performance. Ideal wetting as well as low void rates help to create consistent connections at highest reliability. Heraeus solid core soft solder wires are flux free and especially optimized for high performance components and die attach applications. They are manufactured by a sophisticated extrusion process that leads to extremely tight diameter tolerances and is free of organic contamination and oxides. Heraeus solder wires guarantee a consistent bondline thickness (BLT) and a very low tilt rate.

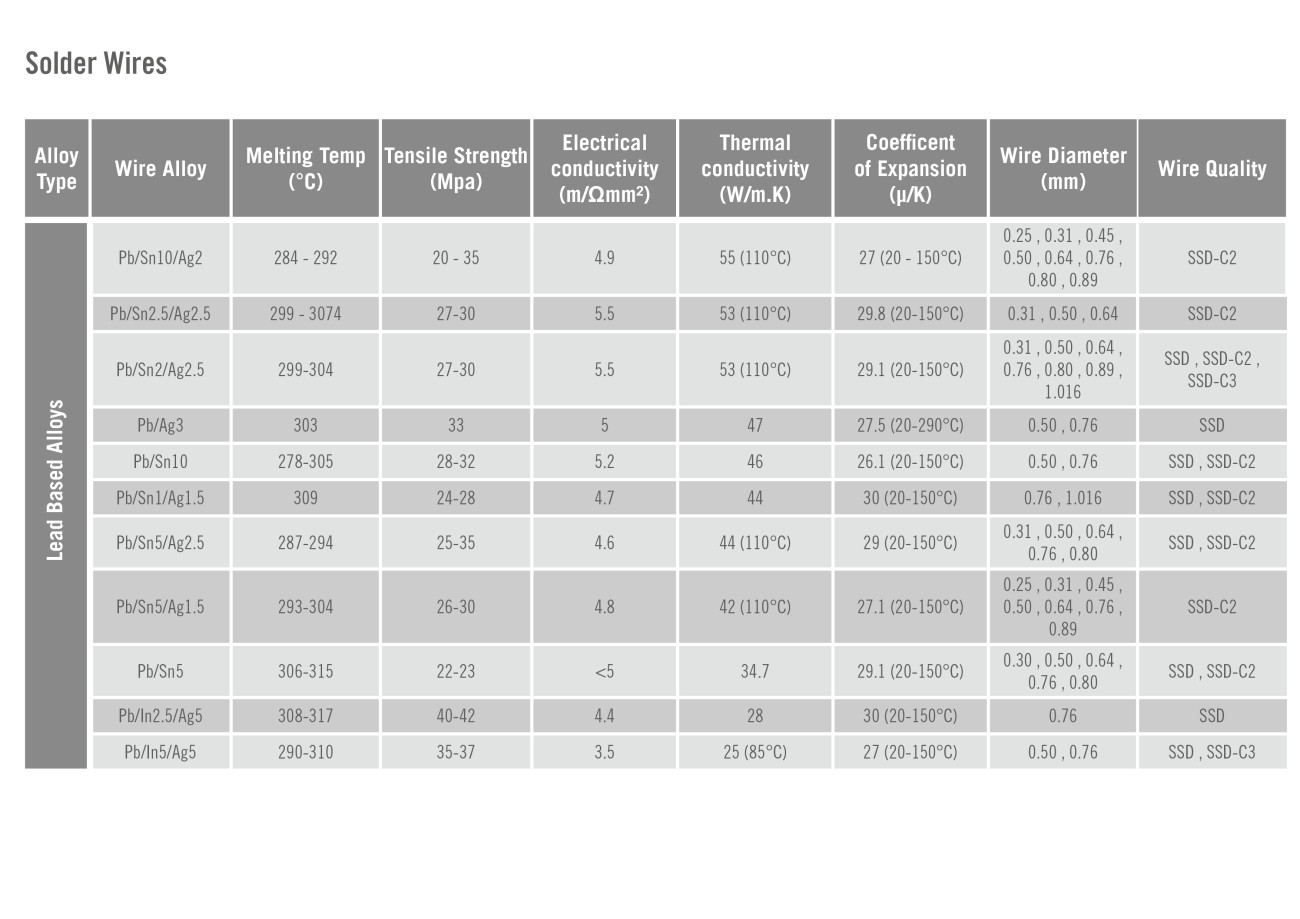

We offer lead-containg as well as lead-free solder wires. Some alloys are available in wetting enhancement options to further improve slump and wetting.

Your benefits at a glance:

High purity ensures an excellent wetting response in the flux free process

Possibility to add wetting enhancing elements that significantly improve the flow properties and the wetting response of the alloy

Compatible with automated processes for efficient manufacturing such as automated wire dispensing processes in vacuum or under an inert gas atmosphere

Wide variety of available diameters (in the range of 10 to 40 mil (0.254 – 1.01 mm) to perfectly match your requirements

Lead-containing as well as lead-free solder wires available

Your benefits in working with Heraeus:

Pretested solutions due to our in-house application centre

Exactly the right solution for your application, adapted to your needs

Go to see more:https://www.heraeus.cn/cn/

Automotive:

Infotainment

Radios

Power electronics in industrial use:

MOSFETs

Power switches

Voltage regulators

IGBTs

DC to DC converters

Communications:

Antennas

RF power

Sensors

Go to see more:https://www.heraeus.cn/cn/