With the pursuit of building cheaper, faster and simpler assembly processes, the Surface-Mount Technology (SMT) replaces more and more the through-hole technology. Heraeus offers a complete portfolio for high reliability solder pastes for SMT applications on Printed Circuit Boards (PCB) and ceramics (e.g. DCB). We match the solder paste to your needs and give you the flexibility to build your optimal solution.

SMT has largely replaced the former through-hole technology for the assembly of electronic circuits on PCBs and ceramics. Since SMT components have either smaller or no leads, they are usually smaller than through-hole components. This leads to a much higher component and weight reduction.

For the setup of an optimal and cost effective production process, it is necessary to find the optimal combination of powder and flux of the solder paste depending on application and substrate. A comprehensive portfolio helps to match the configuration of the solder paste to the requirements of the process. Heraeus produces powder, flux and paste in four different locations. Our decentral solder powder production process guarantees highest yields, consistency and reliability.

Your benefits at a glance:

Solder Powders with highest yield and consistency

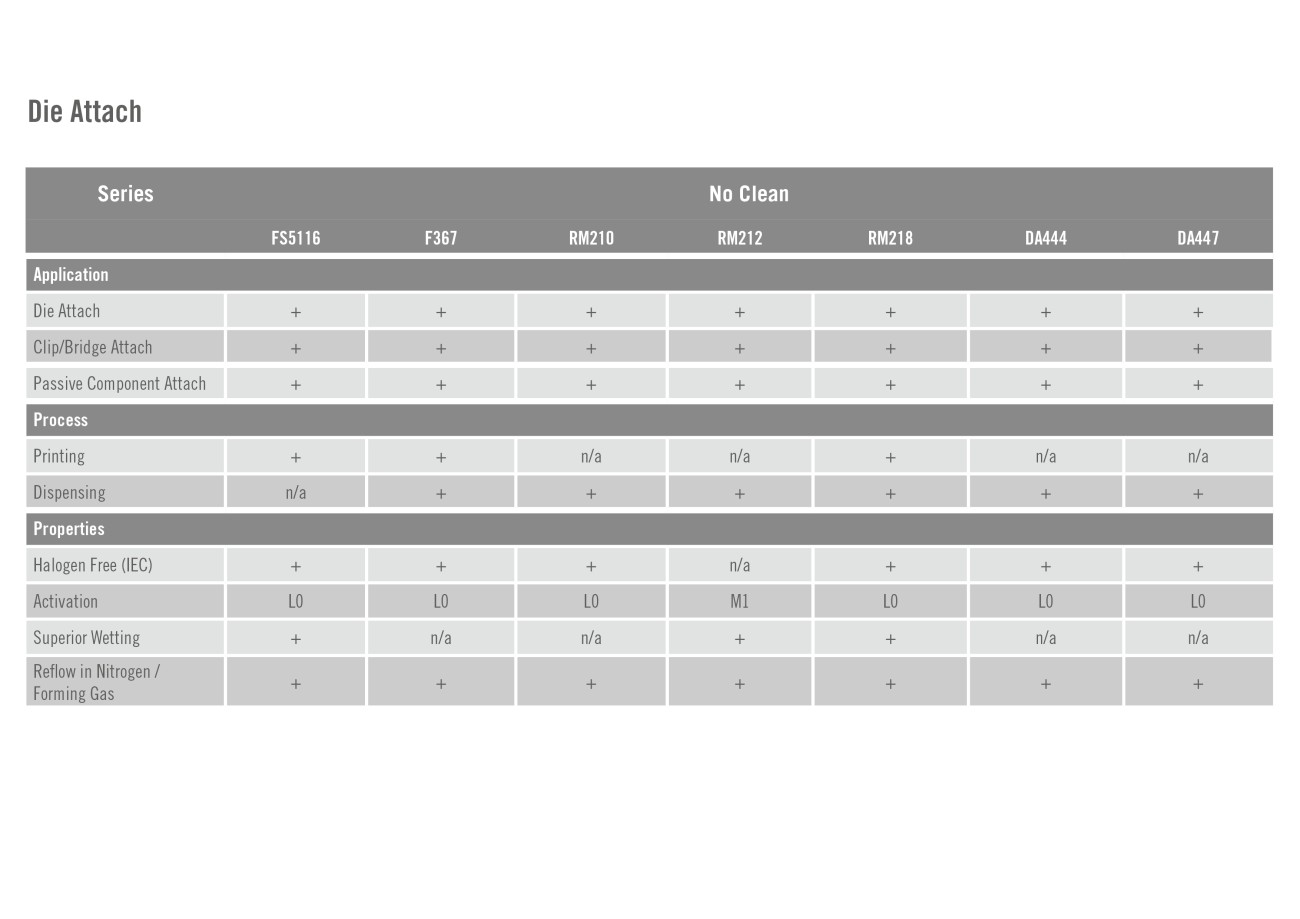

Perfect match to the application due to a wide range of no-clean and water soluble flux systems

Flux families for easy switch of solder alloys, to minimize qualification efforts

Wide range of “green” products (lead-free, halogen-free or zero-halogen)

Proven high reliability solder paste series available (Innorel)

Your advantage in working with Heraeus:

Reliable and fast supply chain worldwide due to paste, powder and flux production sites in China, Singapore and Romania

Pretested solutions due to our in-house application centre

Go to see more:https://www.heraeus.cn/cn/

Automotive

SMT - Board Assembly:

Engine management (Engine Control Unit ECU)

Transmission controllers

Braking (ABS)

Steering and stability systems (ABS, ESP, EPS / EPAS)

DCB – Die Attach on DCB Substrate:

Power electronic modules for the electrification of the drive train (electric and hybrid vehicles)

Industrial Power Electronics

DCB – Die Attach on DCB Substrate:

State-of-the-art IGBT modules for drives, current inverters, and power supplies

Inverters for wind and water power, solar energy, and other renewable energy sources

Trains and other types of transportation

Consumer Electronics & Computing

SMT - Board Assembly:

Smartphones and Tablets

Imaging devices

Servers and Systems

Furthermore, it can be used in other applications in the LED and communications industry.

Go to see more:https://www.heraeus.cn/cn/